AI, cloud services, and other quickly evolving technologies are putting a strain on traditional air cooling’s ability to maintain ideal temperatures for high-density racks. In fact, according to Vertiv’s Data Center Trends 2025 report, average rack densities are predicted to climb to 500-1000kW in AI factories. This increase in high-density data centers doesn’t just require more power, it also requires more advanced cooling systems. Without the proper data center cooling solutions in place, you risk overheating your equipment which will result in unplanned and expensive downtime.

Air cooling has been the traditional choice for many data centers, but this solution isn’t always strong enough to handle the increasing number of high-density racks. Liquid cooling offers the best solution that’s able to keep high-density equipment running and help prevent overheating. Learn more about liquid cooling vs. air cooling and how to know which one to use for your operations in this blog.

How Liquid Cooling vs. Air Cooling Works

Data center cooling is essential to keep your location up and running. Every piece of equipment in your facility produces heat that needs to be removed to prevent overheating and system failure. Air cooling and liquid cooling both get rid of this excess heat but do so in very different ways. The first method uses air as the cooling medium to pick up heat and expel it away from the critical IT equipment. Air cooling works better for less dense environments as it can keep up with the amount of heat produced. This solution generally uses precision cooling systems that offer rack, row, and room cooling units to meet the needs of each facility. Regardless of how much space or density your facility has, there are cooling solutions for every environment like the Liebert PDX Compact DX Cooling System or Liebert ® CW Chilled Water-cooling System.

Perhaps the most important, and most obvious, difference when it comes to liquid cooling vs. air cooling is what each system uses to dispel heat. Instead of circulating air, liquid cooling pumps water or special nonconductive liquids through, or near, your equipment. In liquid cooling, fluid absorbs the heat, lowers its temperature, and then reuses the liquid to start the process over again. Similar to air cooling, there are three main ways liquid cooling can be accomplished:

- Direct-to-chip cooling: sends the coolant straight to the chips in your servers. For example: the Vertiv™ CoolChip CDU

- Rear door heat exchangers: installed on the back of your server racks to remove heat expelled by the servers. For example: the Liebert® DCD Water-Cooled Passive Rack Door

- Immersion cooling: places the entire server in a nonconductive liquid which absorbs any heat that is produced.

All these methods are much more direct than air cooling and can handle higher densities.

Which Data Center Cooling Solution is Right for You?

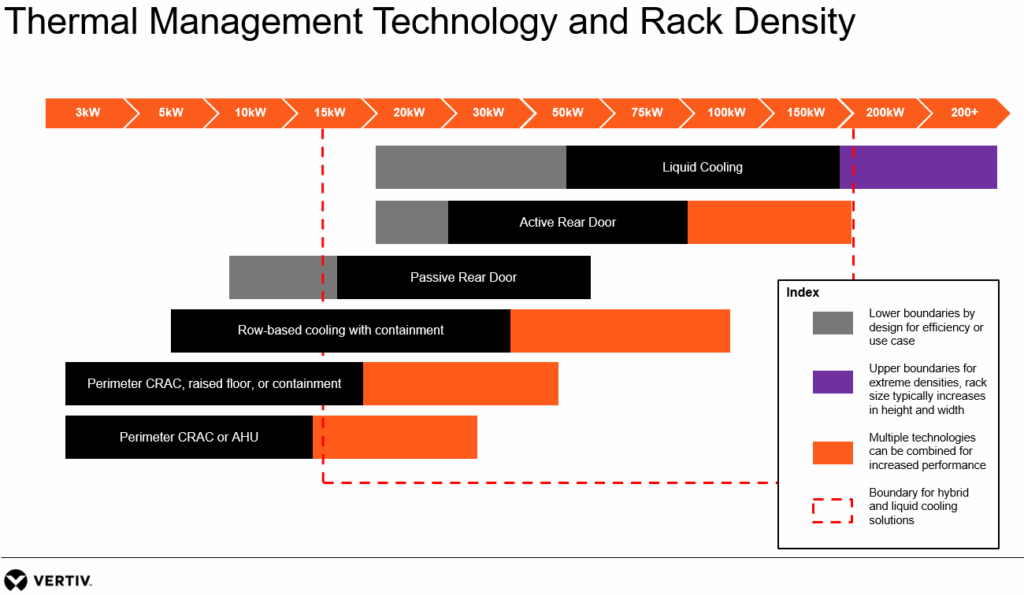

Selecting the right data center cooling solution for your needs largely depends on your rack density. Generally speaking, if you have low density racks that use less than 20kW, then air cooling should suffice. This is because low density racks don’t use as much power or generate as much heat as high-density racks. Therefore, efficient and expensive liquid cooling isn’t necessary. Instead, consider an air room cooling solution like the Liebert DS Direct Expansion Cooling System, which replaces hot air with cool air in your data center.

If you have high density racks that use 20kW or more, liquid cooling should be considered. At 30kW or more, liquid cooling is likely needed. This is because the more power your equipment consumes to perform its workload, the more heat it produces. Traditional air-cooling solutions struggle to keep up with this excess heat because air as a medium can only exchange a limited amount of heat. Therefore, higher densities require the switch to liquid cooling. A hybrid approach (as noted in the image below) using both air and liquid cooling may be the optimal method to effectively remove heat.

As technological advancements like AI push data centers to use more high-density servers, the hybrid cooling approach is becoming more common to remove heat and keep expenses down. In fact, many products are being built with this hybrid approach in mind to ensure data centers can easily switch cooling methods if need be. For example, the new Vertiv™ CoolChip CDU is specifically designed to work with the hybrid model by sending liquid directly to chips to remove heat while AC works to keep the rest of the room cool. This ensures every component in your data center is kept at its optimal temperature. And since this product uses pumps instead of compressors, less energy is needed to operate the device, resulting in even less power consumption.

Want to Learn More About Maintaining Your Facility’s Ideal Environment?

Creating the perfect environment for your equipment to operate in involves more than just rack densities, temperature, and humidity levels. To ensure all your critical devices run smoothly and efficiently, you need a set up that is organized, secure, and up to date. However, it can be difficult to know how to start optimizing your mission critical cooling infrastructure, especially with new technologies coming out at a rapid pace. Sign up for your newsletter to learn about the latest equipment and practices meant to help keep your facility running smoothly no matter what.